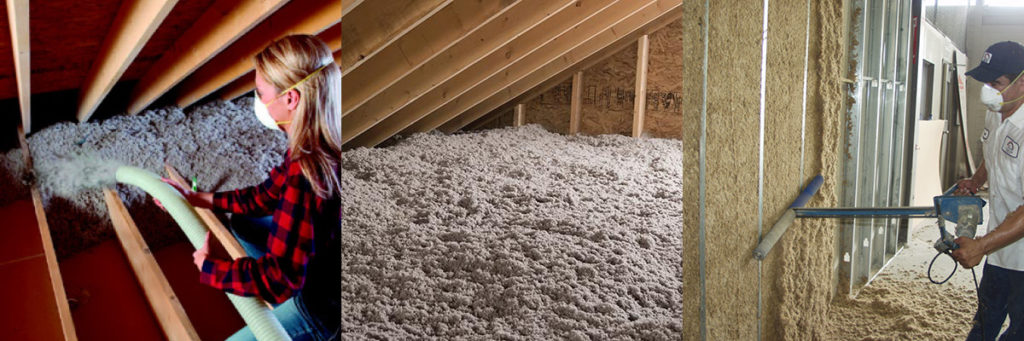

Blown In Insulation

Separates the attic from the home, which will achieve lower energy costs and provide a more thorough comfortable environment. This enables you to start effectively cooling and heating your living spaces better.

Why Blown-In Insulation?

Blown-In insulation is the most efficient solution to put into your attic. It sets up a barrier to keep the hot or cold air in the attic from entering the home. Blown-In insulation, but it is the most beneficial application. It thoroughly covers your attic like a blanket.

Create a comfortable environment for your home.

Home Comfort Options

Celbar Cellulose Insulation

Payless Insulation has been installing Celbar cellulose since 1979 at a 2.2 lb. density per cubic foot. Our experience with this product ensures little to no settling. You pay for your R-Value permanently. Made from recycled paper and cardboard, Celbar is treated with borates (boric acid) which makes it mold and mildew resistant, flame resistant, fire retardant. As a result, rodents will not nest in it, kills roaches and other insects. We are the only company in the country with this special density. We are not interested in shortcuts!

Fiberglass Insulation

Payless Insulation offers white, non-itch, formaldehyde-free fiberglass insulation for our customers. It is an unbonded, virgin fibrous glass blowing insulation. If fiberglass is a must, we will install it properly.

Insulation Removal

When batt or blown insulation becomes less effective due to settling, rodents, age, smoke or water damage, insulation removal becomes a key step to take before installing new, high-performance insulation. Insulation removal also gives you the opportunity to more comprehensively address air leaks with air sealing before installing new insulation. Our costs will include vacuum and disposal.

Wall Insulation

Payless Insulation specializes in pressure filling exterior, sound and attic hot walls (knee walls). Exterior wall cavities whether open or covered by sheetrock, wood, brick or cedar shake can be drilled and pressure filled with minimal disruption to your home.

Floor & Ceiling

For sound or thermal transfer, we pressure fill cavities between the floors, flat roof and cathedral ceilings. We install webbing and filling for a blown in blanket effect when the cavity is exposed. Pressure filling is utilized when ceilings are already in place. This process saves you from having to remove sheetrock to insulate.